304L Stainless Steel Plate Description304L is one of the austenitic stainless steels with a chromium content of at least 18%, a nickel content of at least 8%, and a maximum carbon content of 0.03. 304L stainless steel is an ideal choice for various household and commercial applications, with excelle

Stainless Steel Plate

304L Stainless Steel Plate Description

304L is one of the austenitic stainless steels with a chromium content of at least 18%, a nickel content of at least 8%, and a maximum carbon content of 0.03. 304L stainless steel is an ideal choice for various household and commercial applications, with excellent corrosion resistance, ease of manufacturing and excellent formability. Austenitic stainless steels are also considered to be the easiest to weld among high alloy steels and can be welded by all fusion and resistance welding processes.

Product Parameters

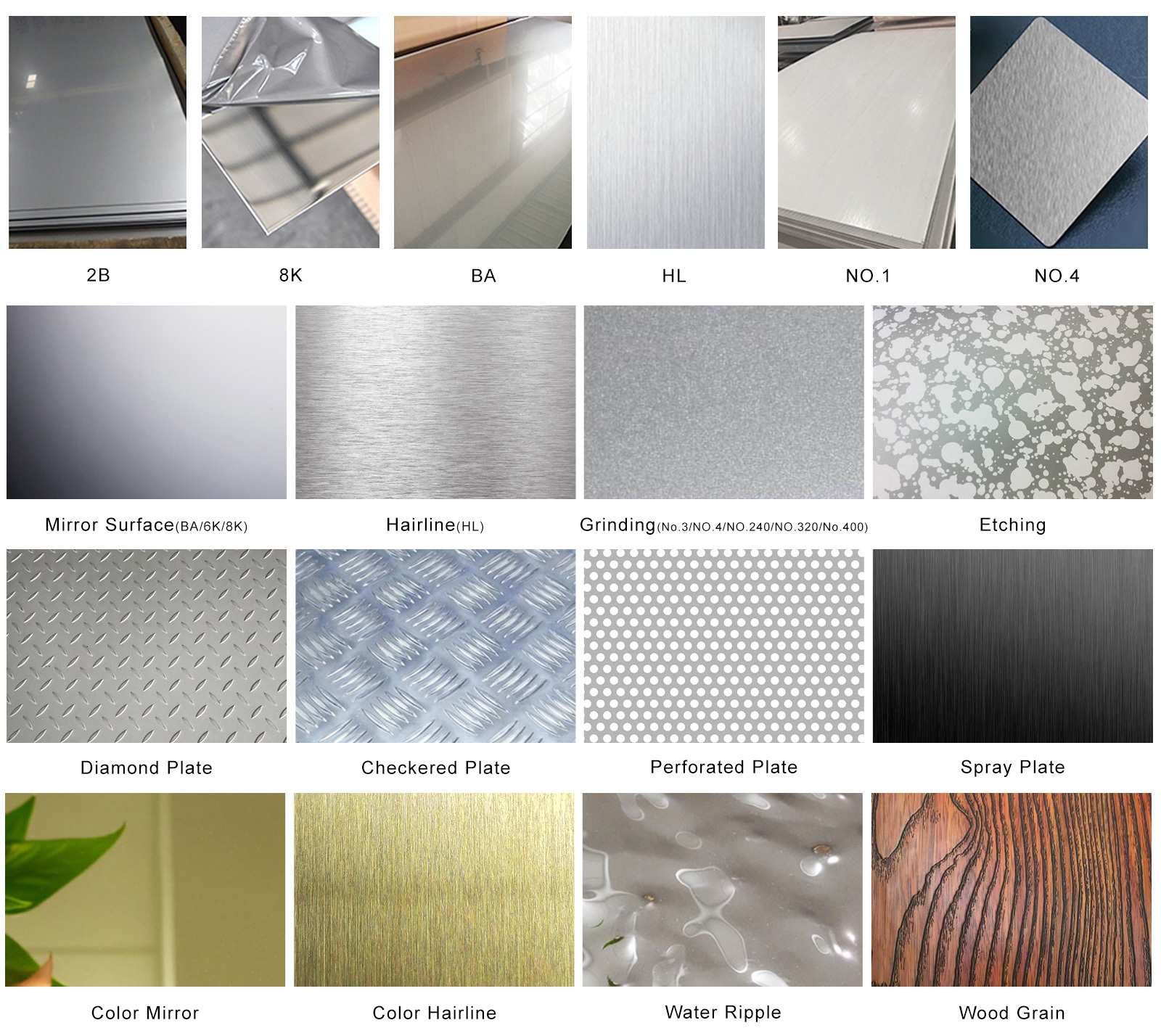

Product Name 304L Stainless Steel Plate Type Plate Thickness 0.3mm-200mm Length 2000mm, 2438mm, 3000mm, 5800mm, 6000mm, 12000mm, etc. Width 40mm-600mm, 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc. Standard ASTM, AISI, JIS, GB, DIN, EN, etc. Surface BA, 2B, NO.1, NO.4, 4K, HL, 8K, etc. Scope of Application Widely used in high temperature and electrical industry, medical equipment construction, chemical, food industry, agriculture and ship parts, food and beverage packaging, Kitchen supplies, trains, airplanes, conveyor belts, vehicles, bolts, nuts, springs and screens, etc. Certificate ISO, SGS, BV, etc. Production Technology Hot Rolling, Cold Rolling Edge Processing Edging, Trimming

Chemical Composition

C Si Mn Cr Ni S P ≤ 0.03 ≤1.0 ≤ 2.0 18.0~20.0 8.0~12.0 ≤ 0.03 ≤ 0.035

Mechanical Properties

Tensile Strength Kb (MPa) Yield Strength σ0.2 (MPa) Elongation D5 (%) Hardness ≥ 520 ≥ 205 ≥ 40 ≤ 187HB ;≤ 90HRB;≤ 200HV

Physical Performance

Density(g/cm³) Modulus of Elasticity(Gpa) Coefficient of Thermal Expansion(10-6/°C) Coefficient of Thermal Conductivity(W/m*K) Resistivity(ΜΩ. cm) 8.03 193 16.9 16.2 72

Surface Selection

Mark Doe