420 Stainless Steel Plate Description420 is a hardenable martensitic stainless steel that contains at least 12% chromium, just enough to provide corrosion resistance. It has good ductility in the annealed condition, but can be hardened to a minimum Rockwell hardness of 50 HRC, which is the highest h

Stainless Steel Plate

420 Stainless Steel Plate Description

420 is a hardenable martensitic stainless steel that contains at least 12% chromium, just enough to provide corrosion resistance. It has good ductility in the annealed condition, but can be hardened to a minimum Rockwell hardness of 50 HRC, which is the highest hardness in the 12% chromium scale. Due to its hardening properties, 420 are not often welded, although this is possible. Martensitic stainless steel is designed for high hardness, and sometimes other properties will be affected to a certain extent. The corrosion resistance is lower than that of ordinary austenite grades, and its effective operating range is limited by its ductility loss at sub-zero temperatures and strength loss due to excessive tempering at high temperatures. The best corrosion resistance is obtained when the metal is hardened and subjected to surface grinding or polishing.

Product Parameters

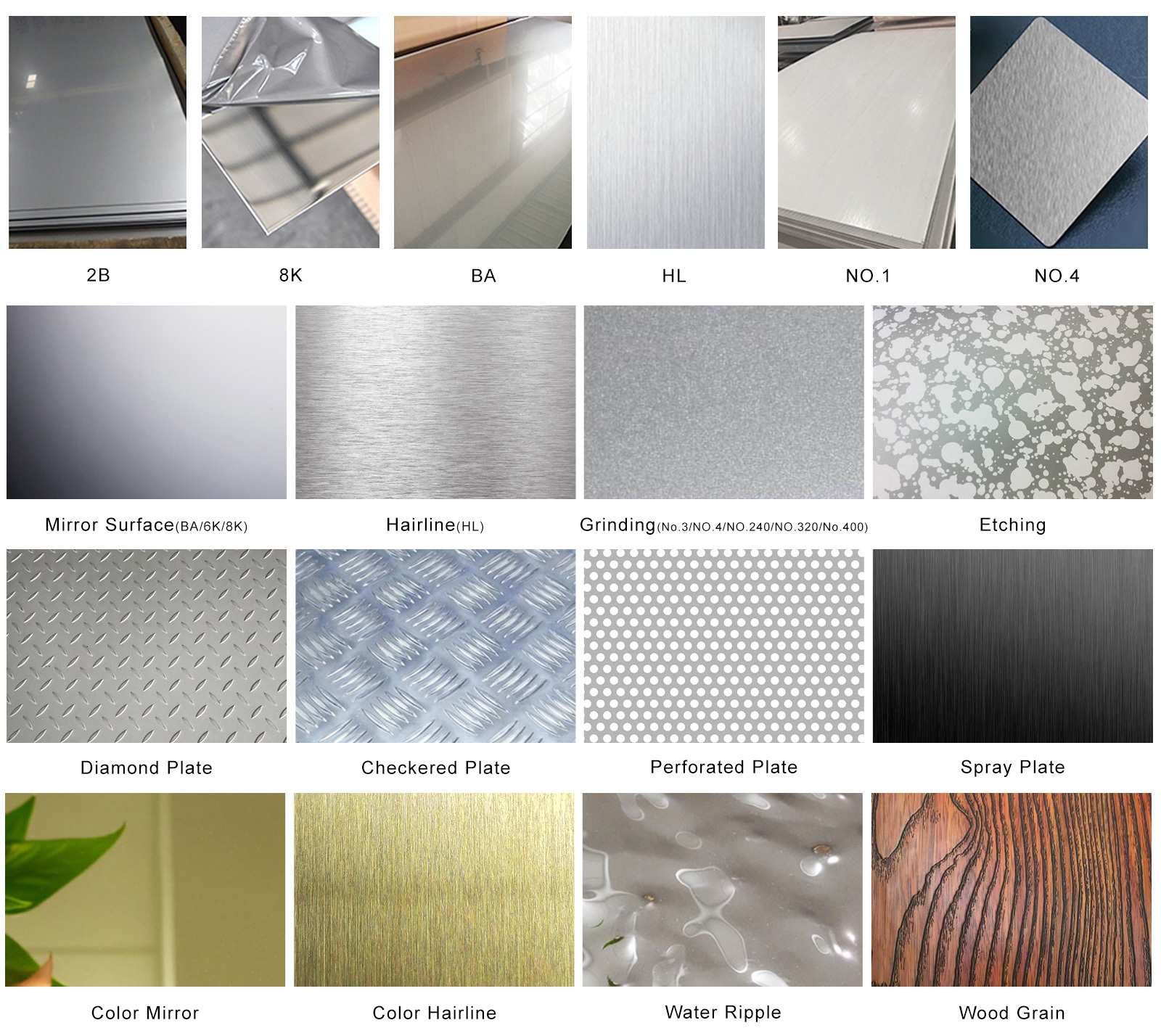

Product Name 420 Stainless Steel Plate Type Plate Thickness 0.3mm-200mm Length 2000mm, 2438mm, 3000mm, 5800mm, 6000mm, 12000mm, etc. Width 40mm-600mm, 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc. Standard ASTM, AISI, JIS, GB, DIN, EN, etc. Surface BA, 2B, NO.1, NO.4, 4K, HL, 8K, etc. Scope of Application Widely used in high temperature and electrical industry, medical equipment construction, chemical, food industry, agriculture and ship parts, food and beverage packaging, Kitchen supplies, trains, airplanes, conveyor belts, vehicles, bolts, nuts, springs and screens, etc. Certificate ISO, SGS, BV, etc. Production Technology Hot Rolling, Cold Rolling Edge Processing Edging, Trimming

Chemical Composition

C Si Mn Cr S P ≤ 0.15 ≤1.0 ≤1.0 12.0~14.0 ≤ 0.03 ≤ 0.04

Mechanical Properties

Tensile Strength Kb (MPa) Yield Strength σ0.2 (MPa) Elongation D5 (%) Hardness ≥634 ≥440 ≥20 Annealing≤ 223HB; quenching and tempering ≥ 192HB

Physical Performance

Density(g/cm³) Modulus of Elasticity(Gpa) Coefficient of Thermal Expansion(10-6/°C) Coefficient of Thermal Conductivity(W/m*K) Resistivity(ΜΩ. cm) 7.74 200 10.2 24.9 55

Surface Selection

Mark Doe